Description

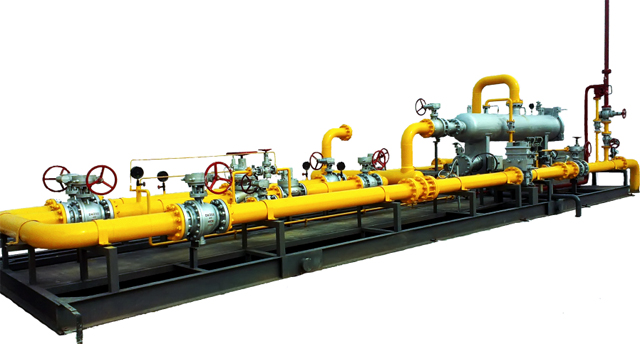

The pressure regulating and metering skid, also called PRMS, is composed of rectangular skid, regulating manifold, control valve, metering pipe, flowmeter, regulating valve, regulating pipe, filter, outlet pipe, inlet manifold, air inlet, outlet manifold, blowdown pipe and safety vent valve. The regulating manifold is in the front, the outlet manifold in the middle, and the inlet manifold in the back. Two parallel metering pipes are horizontally arranged between the two ends of the intake manifold and the regulating pipe, and each metering pipe is successively provided with a control valve, a filter, a pressure gauge, a flowmeter and a control valve; Two parallel regulating pipes are horizontally arranged between the middle part of the outlet manifold and the regulating manifold, and each regulating pipe is successively provided with a control valve, a pressure gauge, a regulating valve and a control valve; The middle part of the air outlet manifold is provided with a belt 90 ° The air outlet pipe of the elbow is provided with an air inlet at the middle side of the air inlet manifold; The inlet manifold and outlet manifold are equipped with safety relief valves.Media used

The pressure regulating and metering skid is mainly used in natural gas, shale gas, artificial gas, liquefied petroleum gas. Air, etc. PRMS can be used for city gate station, distribution station, regional voltage regulation, industrial users and direct combustion equipment, natural gas filling station, public users and so on. Function selection 1. Filtration, voltage regulation and metering. Optional process structure. 2. Optional cabinet structure (cabinet structure is detachable) or skid mounted structure for integration. Debugging, installation, maintenance convenient. 3. It is optional to collect and upload relevant pressure, flow, temperature, differential pressure and other signals. 4, can choose PLC central control system or industrial computer to achieve semi-automatic or full automation. 5. The pipeline can be insulated according to user requirements. 6. Odorizer can be added according to user requirements.Features

1. Design, manufacture and inspection according to Q/ 20208621-x5-2011 (gas pressure regulating device). 2. Set filtration, voltage regulation, metering and safety cutting off. Automatic release, security alarm in one. 3. Beautiful shape, reasonable configuration, reliable performance. 4. High degree of equipment integration, comprehensive testing and performance testing in the factory, convenient on-site installation, compact structure, reasonable layout, small footprint.Specification

| 1 | Temperature range | -20℃±60°C |

| 2 | Inlet pressure | ≤ 25 Mpa |

| 3 | Outlet pressure | 0.02-7.5 Mpa |

| 4 | Flow range | 100-1500000 Nm3/h |